| Products Used | QC1+™ Cleaner HD |

|---|---|

| Product Types Used | Belt Cleaning Solutions , Primary Belt Cleaners |

| Industry | Aggregate |

| Customer | Alamo Cement, San Antonio, TX, USA |

Problem

Alamo Cement, located in San Antonio, was experiencing issues with tacky, clay-heavy raw material from the quarry. The cargo would stick to the return side of two of its stacker conveyor belts, resulting in excessive carryback and accumulation along the belt path. Operators found, even with regular tensioner adjustments, the cleaner blades would not maintain adequate contact with the belt, rendering them ineffective. Due to accumulating carryback, properly positioning the stacker conveyors was a challenge, so each morning 4 employees would have to spend at least 2 hours using shovels and machinery to dig out the portable systems and level them. Operators estimate the issue cost more than $200 per day and took valuable manpower from other priorities.

Solution

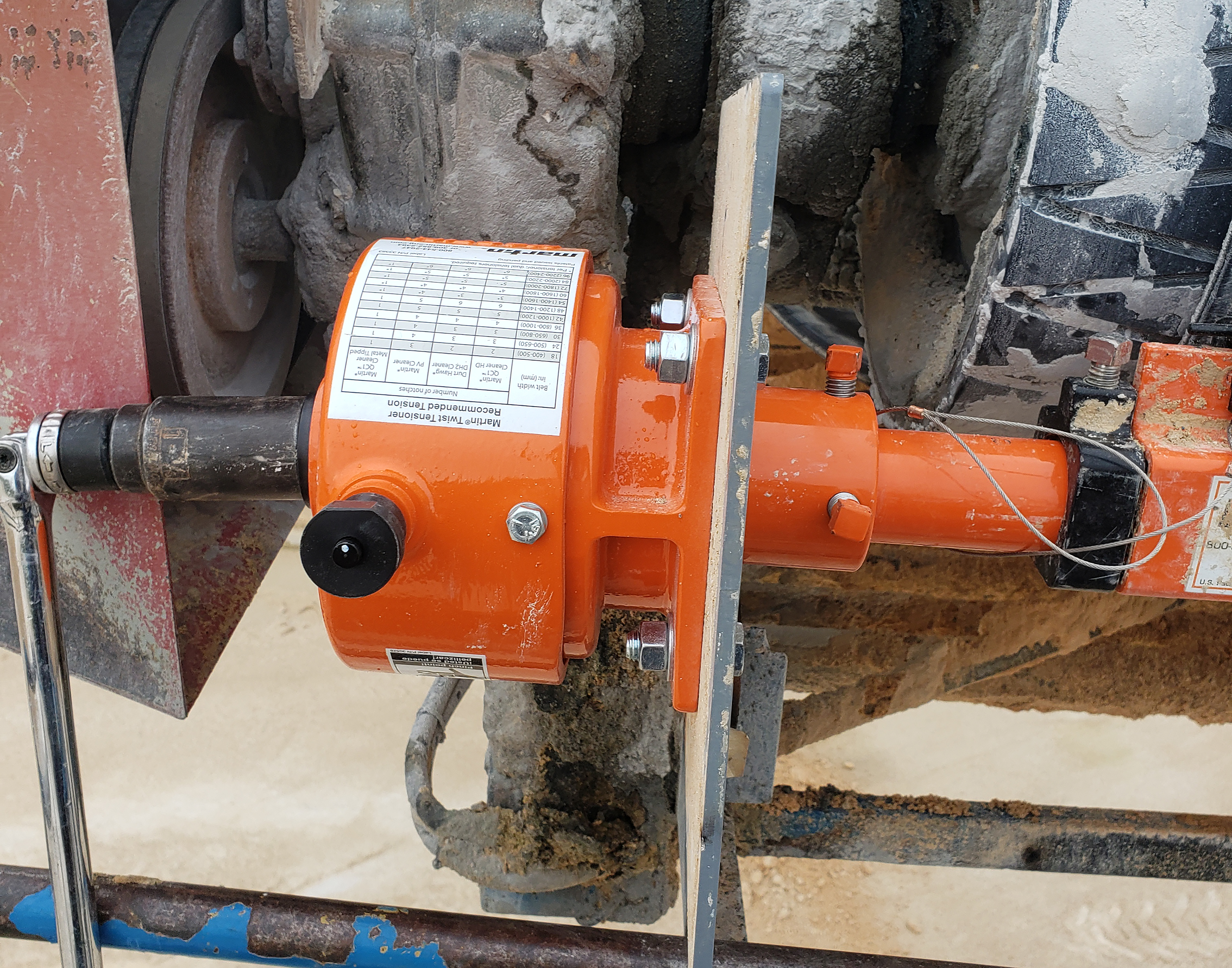

Martin Engineering® Mr. Blade® technicians were invited to examine the issue and provide a solution. They immediately identified problems with how the competitor's existing cleaners had been mounted on the stringer, the use of inadequate blades, and issues with the tensioner. Martin® QC1+™ HD Cleaners were installed to dislodge the caked-on material. Given the space restrictions, technicians chose to install spring tensioners. To offer more consistent tensioning and better blade performance, installers fabricated a mounting plate for the stringer. The Mr. Blade Program safely services and maintains the blades using trained experts driving specially equipped vehicles.

Result

Following the installation, operators tested the cleaner and tensioning system. It offered immediate results on both conveyors, cleaning the belt with little to no carryback. After some time in operation, managers close to the project reported that the morning cleanup ritual had been discontinued and only periodic scheduled cleaning is needed. "The added benefit is to morale," said an operator. "We can focus on more pressing matters than digging out the conveyor." The personalized service and fast return on investment has prompted the plant manager to put together a budget for retrofitting the rest of the conveyors with similar solutions throughout the site.